I’ve been using D’Addario double bass strings for years, and I’ve restrung many a violin, viola, and cello during my high school orchestra director days. I’ve even dug deep into string making on the podcast with D’Addario Orchestral Strings Product Manager Lyris Hung and covered string maintenance and FAQs with D’Addario Orchestral Social Media Strategist Sabrina Brengel.

However, I’ve got a completely different perspective on string making after taking a tour of the D’Addario factory in Farmingdale, New York. It’s a totally fascinating process, and it’s quite different from what I imagined. D’Addario has about 1100 employees worldwide, and almost half of them are employed in the Farmingdale complex that I toured.

View this post on Instagram

First Impressions

Upon meeting Lyris Hung and entering the building, we went upstairs to the expansive and high-ceilinged second-story offices. There’s quite a bit of extra space in the office area of the factory thanks to D’Addario’s adoption of lean manufacturing practices several years ago.

Reorganizing the factory with lean manufacturing practices to eliminate wasted time and supplies actually opened up a lot of space in the factory, and string making operations were consolidated significantly. Interestingly, D’Addario does not eliminate jobs when they eliminate waste. For them, finding ways to be more efficient always seems to open up the opportunity for new developments and investments.

As Lyris took me toward the bowed string production area, we passed through the machine shop. I never realized that all their string making machines are custom-built, with almost no stock parts in use at all. These machines are being continually designed, refined, and repaired in the factory itself.

Passing through the machine shop, we entered the cavernous string production room. Heading toward the cello and bass string machines, the first thing that struck me was how much labor and how many steps go into each individual string.

In the bowed string manufacturing area, each employee on the floor works in front of one or two machines. Each of these machines performs multiple tasks and can be set up to produce all kinds of strings: cello strings, bass strings, fractional sizes, G strings, D strings, etc. Hanging by each machine is a “recipe” much like what you’d see in a kitchen, and each machine is calibrated and programmed to execute a set of steps for that recipe.

There’s quite a bit of switching and reprogramming to switch from, say, a cello D Helicore string to a double bass A Kaplan string. Therefore, once a “recipe” is set, the machines will turn out quite a few of the same string.

How Strings are Made at D’Addario

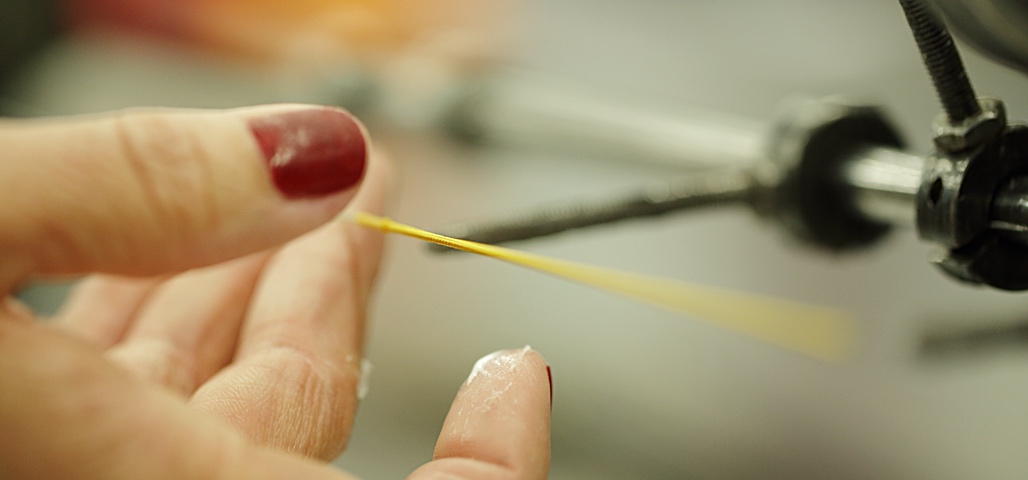

First, a stranded core—remarkably thin-looking to me—is attached to one of the machines, and a series of flattened wire layers are laid out. This flat wire is then wrapped onto the string, which is a mesmerizing and surprisingly slow process. Strings don’t generally go to a lot of machines. Usually just one for winding and one for silking at most.

Unlike round wire used on electric guitar and bass strings, flat wire has very narrow tolerances, and it takes quite a while to get a layer down. The machine gets the core spinning, and the wire is then methodically laid down from end to end.

Many types of strings use damping between the layers to allow the strings to respond more quickly and to change direction in the Helmholtz slip-stick pattern.

Handmade in America

In my mind, I’d pictured some fast and complex assembly line setup, with hundreds of strings being churned out in tandem by a bunch of robots.

Nothing could be further from the truth, especially in the bowed string area. These strings really are hand made, despite all the machines involved.

Advantages of Moving Production In-House

D’Addario is making pretty much every single thing they’re using in-house—another lean manufacturing practice that allows for quick manufacturing pivots and rapid experimentation. It was really cool to see just how many different combinations of components can go into a string.

There are so many different cores that a string can be made of, like solid steel, stranded steel, or synthetic core materials like Zyex. Flat wire also comes from plenty of different materials, and each combination of core and wrapping creates a radically different feel under the hand. It’s remarkable, in fact, just how different playing on one material versus another can be in the tactile experience of the player.

The finished string is then deposited in a receptacle on the machine. Later, it will either be packaged into an individual envelope as a single string or with a set. This packaging is all created and packed just a few dozen yards away, again by an employee individually stuffing envelopes. They’re packed into corresponding boxes and will later be taken to the D’Addario distribution facility located a few buildings away.

Large Production on a Human Scale

It’s remarkable to me how a string like Kaplan, Zyex, Helicore, or any of the other D’Addario brands is made from start to finish in such a compact space. I had some image of a vast aircraft hanger in mind, when in reality it’s a well-lit, relatively small area of D’Addario’s factory that’s generating all of these bowed strings.

The violin and viola string making machines are much smaller, like you’d expect. Despite being smaller and consequently faster, it’s remarkable how many steps and how much time goes into each individual string.

Having witnessed all of these string winders in action, and then contrasted them with the speed of the electric guitar and electric bass string machines in the next area, I immediately understood why each bowed bass string costs $20-30, while you can get an entire set of six guitar strings for less than half that cost. There’s a lot of labor that goes into each string, plus the complexity of the process and the materials involved makes me surprised that it doesn’t cost even more!

Round Wound Strings

Next up, Lyris took me into the round-wound string area. This area is grouped into a particular cell, labeled by color: Red Cell, Blue Cell, and the like. This organizational system is again a result of lean manufacturing. Everyone in that particular cell is responsible for the product coming out of that cell, making it much simpler to trace manufacturing problems directly to the source.

I could clearly see how the round-wound strings are assembled from the back of the cell to the front. These machines are all smaller, and it’s remarkable to see how much easier it is to lay round wire down onto these strings.

Nylon Strings

Recently, D’Addario has even begun to make nylon strings in-house. The nylon extrusion machine is totally fascinating. It is an extremely long series of machines that are kind of like a massive taffy-pulling setup. The nylon plastic starts off as a wide and thick strand and is pulled through the first machine fairly slowly. Each machine pulls it slightly faster than the last, with jets of air cooling the nylon as it stretches ever thinner. The nylon is moving quite rapidly near the end, and it finally gets cut into the correct length and deposited.

D’Addario applies various treatment processes to metal, nylon, and other building materials to ensure that these materials will not get brittle. They’re also creating nearly everything, even the colorful ball ends on guitar strings, in house. By not relying on outside supply chains, D’Addario is able to adapt quickly to demand and not rely on production bottlenecks outside of their control.

Experimentation and Innovation

With something like string making, you might think that there’s a way to do it that has been established for hundreds of years, and there’s no real innovation going on these days. I was struck, however, by just how experimental D’Addario is, and how they’re always trying out new machines, new materials, and new processes. It’s actually really exciting to see all these new machines that have come on board only within the last few weeks. Clearly, these folks are continuing to refine and evolve their craft, coming up with new innovations in string making.

Learn More

D’Addario has a wealth of resources on their site covering the string-making process, silking, string tension, FAQs, and other topics, and this is a great place to start learning more about strings.

You can also check out these string-specific podcasts that I’ve put out with D’Addario employees and artists:

- How Strings Are Made with Lyris Hung

- Strings Q&A with Sabrina Brengel

- Perspectives on strings from various D’Addario artists

Bass News Right To Your Inbox!

Subscribe to get our weekly newsletter covering the double bass world.